![]() Home / Services / Tankcleaning / Tank 2.0 – Zero – Emission Technology

Home / Services / Tankcleaning / Tank 2.0 – Zero – Emission Technology

Tank 2.0 Process description

![]() Closed flushing procedures for storage tanks for flammable liquids

Closed flushing procedures for storage tanks for flammable liquids![]() Integrated heat generation

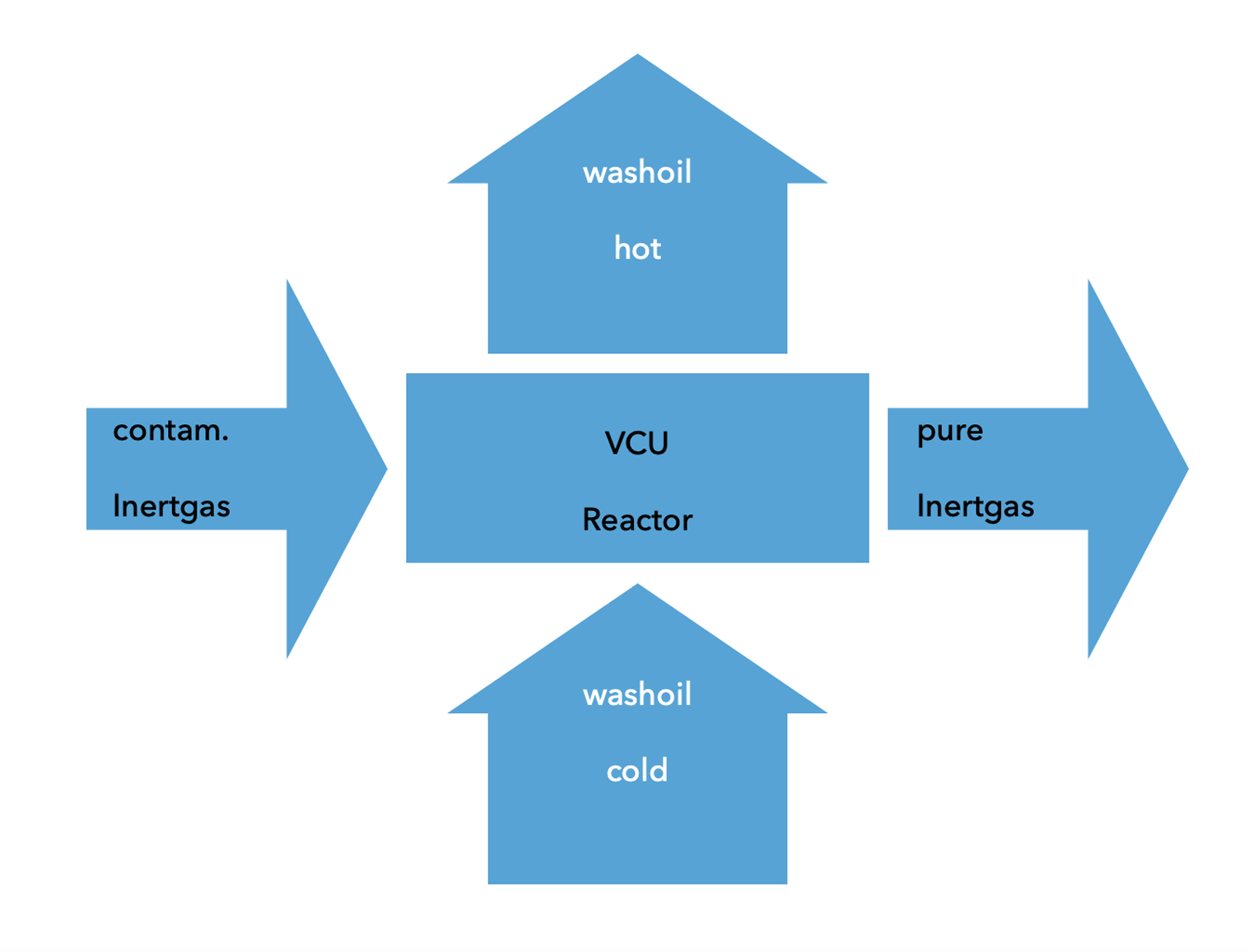

Integrated heat generation![]() Integrated inert gas generation

Integrated inert gas generation

no hydrocarbon emissions![]() Chemical / thermal processing

Chemical / thermal processing![]() Use of market-tested systems

Use of market-tested systems![]() First succesful projects

First succesful projects

Tank 2.0 closed washing procedure

Tank 2.0 Argumente

Zero – Emission Technology

![]() Overachievement of emission limits according to TA Luft

Overachievement of emission limits according to TA Luft![]() Customer and regulatory requirements are fully or over-fulfilled

Customer and regulatory requirements are fully or over-fulfilled

Low costs

![]() no inert gas generator needed

no inert gas generator needed![]() no steam generator needed

no steam generator needed![]() no air purification measures necessary

no air purification measures necessary![]() 3 operators for the overall system / layer

3 operators for the overall system / layer

Patent protection